Response Surface Methodology for Optimization of Free Fatty Acid Glycerolysis in Crude Palm Oil Using Crude Glycerol

Main Article Content

Abstract

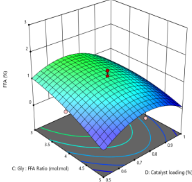

The free fatty acid (FFA) content in crude palm oil (CPO) must stay within acceptable limits to meet product quality standards. As a result, managing and reducing FFA levels is crucial for preserving CPO quality. This study aimed to evaluate the impact of glycerolysis on reducing FFA levels in CPO under Response Surface Methodology (RSM). Four key operational parameters affecting FFA reduction were examined: reaction temperature (65–85°C), stirring speed (150–250 rpm), molar ratio of glycerol to FFA (3:1–5:1), and catalyst loading (0.5–1 wt.%). A statistical analysis employing analysis of variance (ANOVA) was conducted to evaluate the importance of each factor. The optimal conditions for glycerolysis, which successfully reduced the FFA content in CPO from 6.15% to 0.24%, were identified as a reaction temperature of 75.17°C, stirring speed of 235.06 rpm, glycerol to FFA molar ratio of 3.57:1, and catalyst loading of 0.98 wt.%, with a reaction duration of 90 minutes. The statistical models demonstrated high significance, with a p-value <0.0001 and a coefficient of determination (R²) of 0.95. The reliability of these models was further validated through experimental trials under the optimal conditions, yielding an actual FFA content of 0.27%, confirming the model’s predictive accuracy. This study highlights the utilization of crude glycerol for the reduction of FFA levels through glycerolysis reactions. The results of this study are expected to serve as an alternative to the esterification processes that have been applied in the industry to lower FFA levels in palm oil.

Downloads

Article Details

Section

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.

How to Cite

References

Adeyemi MM, Muhammad KM, Umoru PE. ERRATUM: Optimization of biodiesel production from seeds of cotton and calabash via in situ transesterification using CaO as catalyst. Trop J Nat Prod Res. 2023; 7(11): 2432–2436

Kara K, Ouanji F, Lotfi EM, Mahi MEl, Kacimi M, Ziyad M. Biodiesel production from waste fish oil with high free fatty acid content from Moroccan fish-processing industries. Egypt J Pet. 2018; 27(2): 249–255.

Aparamarta HW, Gunawan S, Azhar B, Aditya HT, Widjaja A, Ju YH. Comparative study of batchwise solvent extraction and the microwave assisted extraction method for the purification of triglyceride for biodiesel feedstock from crude Calophyllum inophyllum oil (CCIO). Int J Technol. 2019; 10(3): 551–560

Tu Q, Lu M, Knothe G. Glycerolysis with crude glycerin as an alternative pretreatment for biodiesel production from grease trap waste: Parametric study and energy analysis. J Clean Prod. 2017; 162: 504–511

Supardan MD, Adisalamun, Lubis YM, Annisa Y, Satriana, Mustapha WAW. Effect of co-solvent addition on glycerolysis of waste cooking oil. Pertanika J Sci Technol. 2017; 4: 1203–1210

Attarbachi T, Kingsley M, Spallina V. Waste-derived low-grade glycerol purification and recovery from biorefineries: An experimental investigation. Biofuels Bioprod Biorefining. 2024; 18: 1475–1494

Suriaini N, Arpi N, Syamsuddin Y, Supardan MD. Use of crude glycerol for glycerolysis of free fatty acids in crude palm oil. Int J Technol. 2021; 12(4): 760–769

Satriana, Arpi N, Supardan MD, Gustina RT, Mustapha WAW. Low-temperature glycerolysis of avocado oil. AIP Conf Proceed. 2018; 1940: 020100

Wangi IP, Supriyanto, Sulistyo H, Hidayat C. High shear reactor for glycerolysis—Interesterification palm stearin-olein blend: Reaction kinetics and physical properties. J Am Oil Chem Soc. 2024; 101(6): 589–600

Selemani A, Kombe GG. Glycerolysis of high free fatty acid oil by heterogeneous catalyst for biodiesel production. Results Eng. 2022; 16: 100602

Buchori L, Djaeni M, Ratnawati R, Retnowati DS, Hadiyanto H, Anggoro DD. Glycerolysis using KF/CaO-MgO catalyst: Optimisation and reaction kinetics. J Teknol. 2020; 82(5): 109–116

Miao S, Lin D. Monoglycerides: Categories, structures, properties, preparations, and applications in the food industry. Editor(s): Laurence Melton, Fereidoon Shahidi, Peter Varelis, Encyclopedia of Food Chemistry, Academic Press, 2019; 155–163.

Idris NA, Lau HLN, Wafti NSA, Mustaffa NK, Loh SK. Glycerolysis of palm fatty acid distillate (PFAD) as biodiesel feedstock using heterogeneous catalyst. Waste Biomass Valori. 2021; 12(2): 735–744

Kombe GG, Temu AK, Rajabu HM, Mrema GD, Lee KT. Low temperature glycerolysis as a high FFA pre-treatment method for biodiesel production. Adv Chem Engineer Sci. 2013; 03(04): 248–254

Binhayeeding N, Klomklao S, Sangkharak K. Utilization of waste glycerol from biodiesel process as a substrate for mono-, di-, and triacylglycerol production. Energy Procedia. 2017; 138: 895–900

Supardan MD, Fahrizal, Moulana R, Safrida D, Satriana, Mustapha WAW. Optimisation of process parameter conditions for for biodiesel production by reactive extraction of jatropha seeds. J Eng Sci Technol. 2017; 12(3): 847–859

Sri KA, Kamiliyah HN, Runadi D. Enhanced extraction of Antishigellosis compounds from Ficus elastica leaves: A response surface methodology approach. Trop J Nat Prod Res. 2025;9(2):670–676.

Nafisah U, Wikantyasning ER, Sukmawati A. Optimization of nanostructured lipid carriers for essential oil of Artemisia herba-alba. Trop J Nat Prod Res. 2024;8(12):9578–9585.

Kurniatin PA, Ginting MF, Khoerunnisa A, Setyawati I, Artika IM, Ambarsari L, Nurcholis W. Optimization of antimicrobial peptide (AMP) extraction from Justicia gendarussa leaves using Box-Behnken design. Trop J Nat Prod Res. 2024; 8(6): 7416–7422

Chanthon N, Ngaosuwan K, Kiatkittipong W, Wongsawaeng D, Appamana W, Quitain AT, Assabumrungrat S. High-efficiency biodiesel production using rotating tube reactor: New insight of operating parameters on hydrodynamic regime and biodiesel yield. Renew Sustain Energy Rev. 2021; 151: 111430

Hiranlordsanti P, Ngaosuwan K, Weeranoppanant N, Mens W, Chanthanumataporn M, Chanthon N, Wongsawaeng D, Kiatkittipong W, Assabumrungrat S. Application of Box-Behnken design in monoglycerides production via glycerolysis of palm oil using homogenizer reactor. Ind Crops Prod. 2024; 222(2): 119631

Miyuranga KAV, Arachchige USPR, Jayasinghe RA, Samarakoon G. Purification of residual glycerol from biodiesel production as a value-added raw material for glycerolysis of free fatty acids in waste cooking oil. Energies. 2022; 15: 8856

Rocha-Meneses L, Hari A, Inayat A, Yousef LA, Alarab S, Abdallah M, Shanableh A, Ghenai C, Shanmugam S, Kikas T. Recent advances on biodiesel production from waste cooking oil (WCO): A review of reactors, catalysts, and optimization techniques impacting the production. Fuel. 2023; 348: 128514

Subroto E, Indiarto R, Pangawikan AD, Lembong E, Hadiyanti R. Types and concentrations of catalysts in chemical glycerolysis for the production of monoacylglycerols and diacylglycerols. Adv. Sci., Technol. Engin. Systems 2021; 6(1), 612–618.

Chetpattananondh P, Tabtimmuang A, Prasertsit K. Enhanced glycerolysis of fatty acid methyl ester by static mixer reactor. ACS omega 2024; 9(38), 39703–39714.